Mitsubishi Triton wiring diagrams are essential for understanding and maintaining the vehicle’s electrical systems. They provide detailed schematics to diagnose issues and guide repairs effectively.

1.1 Importance of Wiring Diagrams for Vehicle Maintenance

Wiring diagrams are crucial for diagnosing and repairing electrical issues in the Mitsubishi Triton. They provide a clear visual representation of the vehicle’s electrical circuits‚ enabling mechanics to identify faults efficiently. Access to detailed PDF manuals ensures accurate troubleshooting and maintenance‚ reducing the risk of errors during repairs. These diagrams are essential for both professional technicians and DIY enthusiasts‚ offering a comprehensive guide to understanding the vehicle’s electrical systems.

1.2 Overview of Mitsubishi Triton Electrical Systems

The Mitsubishi Triton features a complex electrical system‚ comprising engine wiring‚ audio systems‚ and lighting circuits. These systems are interconnected through detailed wiring diagrams‚ ensuring proper functionality. The Triton’s electrical architecture supports advanced components like the multi-entertainment system and engine control units‚ making it essential to refer to official PDF manuals for accurate system understanding and repairs.

Understanding Mitsubishi Triton Wiring Diagrams

Understanding Mitsubishi Triton wiring diagrams involves interpreting detailed schematics that guide electrical system repairs and modifications. These diagrams are crucial for identifying components and ensuring accurate troubleshooting and installations.

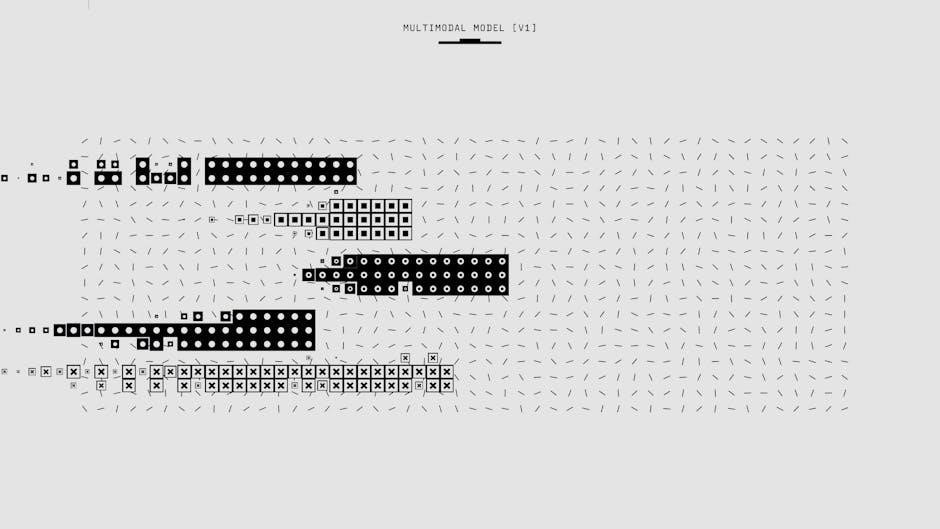

2.1 Key Components of a Wiring Diagram

A Mitsubishi Triton wiring diagram includes essential elements like wire color codes‚ connectors‚ fuses‚ and circuit pathways. These components help technicians identify electrical connections‚ troubleshoot faults‚ and perform repairs or modifications accurately. The diagrams also highlight power sources‚ ground points‚ and relay locations‚ ensuring a clear understanding of the vehicle’s electrical system for effective maintenance and upgrades.

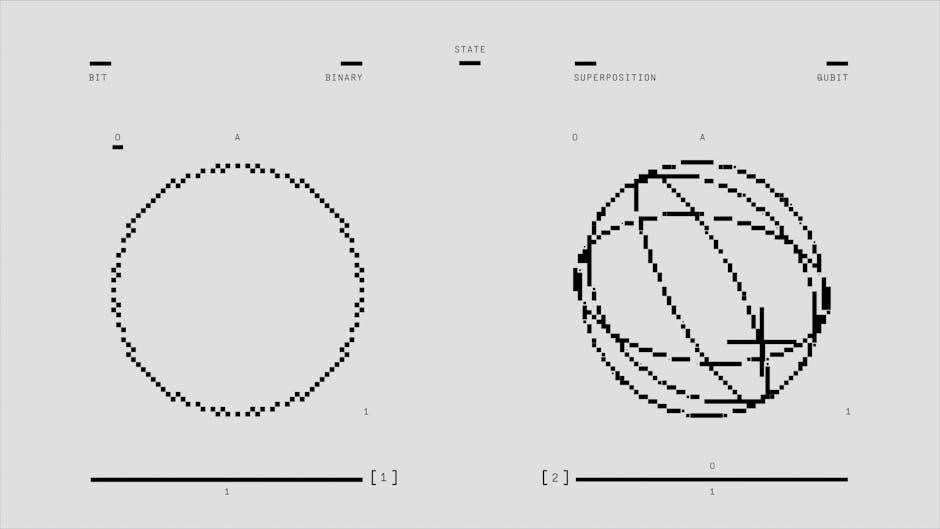

2.2 Symbols and Abbreviations Used in Wiring Diagrams

Mitsubishi Triton wiring diagrams use standardized symbols and abbreviations to represent components like fuses‚ relays‚ and connectors. Symbols for ground points‚ power sources‚ and wire colors ensure clarity. Abbreviations like “G” for ground or “B” for battery help technicians quickly identify connections. Understanding these symbols is crucial for accurately interpreting the diagram and performing electrical repairs or modifications efficiently.

Types of Wiring Diagrams for Mitsubishi Triton

Mitsubishi Triton wiring diagrams include engine wiring for motor control‚ stereo diagrams for audio systems‚ and lighting diagrams for electrical accessories‚ ensuring comprehensive system coverage.

3.1 Engine Wiring Diagrams

Mitsubishi Triton engine wiring diagrams detail the electrical circuits for the engine control unit‚ fuel injection systems‚ and sensors; These diagrams help technicians diagnose issues like faulty sensors or wiring‚ ensuring proper engine performance and efficient repairs. They are essential for maintaining the vehicle’s powertrain and addressing complex electrical problems effectively.

3.2 Stereo and Audio System Wiring Diagrams

Mitsubishi Triton stereo and audio system wiring diagrams provide detailed schematics for installing or repairing the vehicle’s entertainment system. These diagrams outline connections for amplifiers‚ speakers‚ and multimedia interfaces‚ ensuring proper functionality. They also cover integration with aftermarket systems‚ such as DVD players and Bluetooth modules‚ making it easier to upgrade or troubleshoot audio components effectively. This guide is essential for maintaining or enhancing the vehicle’s audio capabilities.

3.3 Lighting and Electrical Accessory Wiring Diagrams

Mitsubishi Triton lighting and electrical accessory wiring diagrams detail the circuits for headlights‚ taillights‚ fog lamps‚ and interior lighting. These diagrams also cover auxiliary systems like alarms‚ winches‚ and aftermarket accessories. They provide clear pathways for power and ground connections‚ ensuring proper functionality and safety. This guide is crucial for troubleshooting faulty lights or adding custom electrical components to the vehicle.

How to Find and Download Mitsubishi Triton Wiring Diagrams

Mitsubishi Triton wiring diagrams are available via official Mitsubishi sources‚ third-party websites‚ and forums. Ensure diagrams are verified for accuracy and compatibility with your vehicle’s model year.

4.1 Official Mitsubishi Sources

Official Mitsubishi sources provide authentic wiring diagrams for the Triton‚ ensuring accuracy and reliability. These diagrams are typically available in PDF format and can be accessed through Mitsubishi’s official website or authorized dealers. They cover various models‚ including the 2015 and 2016 Triton‚ and are essential for precise repairs and customizations.

4.2 Third-Party Websites and Forums

Third-party websites and forums offer a wealth of wiring diagrams for the Mitsubishi Triton. Platforms like forums and specialized automotive sites provide free PDF downloads for various models‚ including the 1996-2004 and 2015 MY Triton. These resources are often shared by enthusiasts and technicians‚ making them valuable for DIY repairs and modifications.

4.3 Tips for Verifying Diagram Accuracy

Verify wiring diagram accuracy by cross-referencing with your vehicle’s make‚ model‚ and year. Ensure the PDF matches your Triton’s specifications and electrical system. Check for updates or revisions and download from trusted sources to avoid errors or mismatches in the diagrams.

Interpreting Mitsubishi Triton Wiring Diagrams

Understanding wiring diagrams involves identifying components‚ symbols‚ and pathways. Use color codes and labels to trace circuits‚ ensuring accurate repairs and customizations for your Triton’s electrical system.

5.1 Identifying Wires and Connectors

Identifying wires and connectors in Mitsubishi Triton diagrams is crucial for accurate repairs. Use color codes‚ thickness‚ and connector shapes to trace circuits. Refer to the legend for abbreviations and symbols‚ ensuring each wire’s purpose is clear. This step helps in diagnosing faults and prevents misconnections‚ essential for safe and effective electrical system maintenance.

5.2 Understanding Circuit Pathways

Understanding circuit pathways in Mitsubishi Triton wiring diagrams involves tracing the flow of electrical current from the power source to components. Start from the battery or ECU‚ following wires through connectors and fuses. Diagrams reveal how circuits branch and interact‚ aiding in troubleshooting. Recognizing common pathways‚ like those for lighting or audio systems‚ helps isolate faults and ensures proper repairs.

5.3 Troubleshooting Common Issues

Troubleshooting common issues with Mitsubishi Triton wiring diagrams involves identifying faulty connections‚ blown fuses‚ or malfunctioning components. By analyzing the circuit pathways‚ you can pinpoint disruptions in power flow. Common problems include faulty ground wires‚ open circuits‚ or short circuits. Referencing the diagram helps locate the source of the issue‚ ensuring accurate diagnostics and effective repairs to restore electrical system functionality.

Safety Precautions When Working with Wiring Diagrams

Always disconnect the battery to prevent short circuits. Use insulated tools to avoid electric shocks. Ensure proper insulation of wires and follow manufacturer guidelines for safe repairs.

6.1 Essential Safety Tools and Equipment

Use insulated screwdrivers‚ wire cutters‚ and pliers to prevent electrical shocks. Safety gloves and goggles protect against accidents. A multimeter is crucial for voltage testing. Ensure a fire extinguisher is nearby. Always disconnect the battery before starting work to avoid short circuits and potential damage to the electrical system of your Mitsubishi Triton.

6.2 Best Practices for Electrical System Repairs

Always consult the Mitsubishi Triton wiring diagram for accurate repairs. Disconnect the battery to prevent power surges. Use appropriate tools to avoid damaging wires or connectors. Test components before replacement to confirm issues. Avoid shortcuts‚ as they can lead to system malfunctions. Ensure all connections are secure and insulated to prevent short circuits and ensure long-term reliability.

Common Mistakes to Avoid When Using Wiring Diagrams

Common mistakes include misidentifying wire colors‚ overlooking ground connections‚ and ignoring fuse diagrams. Always verify diagram accuracy and consult official sources to ensure reliable repairs.

7.1 Misidentifying Wire Colors and Codes

Misidentifying wire colors and codes is a common error. Mitsubishi Triton diagrams use specific color codes for wires‚ ensuring proper connections. Always cross-reference with the official manual or PDF guides to avoid mismatches‚ which can lead to electrical failures or system malfunctions. Using accurate diagrams prevents such issues‚ ensuring safe and effective repairs of the vehicle’s electrical systems.

7.2 Overlooking Ground Wire Connections

Overlooking ground wire connections is a critical mistake. Ground wires are essential for circuit completion and safety. Neglecting them can lead to electrical malfunctions or component damage. Always verify ground connections using the wiring diagram. Ensure all ground points are clean and secure. Proper grounding prevents system failures and ensures reliable operation of the Mitsubishi Triton’s electrical systems‚ as outlined in the PDF manuals and guides.

7.3 Ignoring Fuse and Relay Diagrams

Ignoring fuse and relay diagrams is a common mistake that can lead to electrical system failures. These diagrams are crucial for understanding power distribution and circuit protection. Without consulting them‚ diagnosing issues becomes challenging‚ and incorrect repairs may cause power surges or component damage. Always refer to the fuse and relay sections in the Mitsubishi Triton wiring diagram PDF to ensure proper electrical system functioning and safety.

Tools and Materials Needed for Wiring Repairs

Essential tools include multimeters‚ wire strippers‚ and crimpers. Materials like connectors‚ electrical tape‚ and heat shrink tubing are crucial for safe and reliable wiring repairs.

8.1 Basic Toolkit for Electrical Repairs

A basic toolkit for electrical repairs includes a multimeter‚ wire strippers‚ screwdrivers‚ pliers‚ and electrical tape. These tools are essential for diagnosing and repairing wiring issues safely and efficiently.

8.2 Specialized Tools for Complex Wiring Jobs

For complex wiring jobs‚ specialized tools like an oscilloscope‚ wiring diagram manual‚ and crimping tools are essential. An ECU programmer and advanced circuit testers help diagnose and repair intricate electrical systems. These tools ensure precise connections and troubleshooting‚ making them indispensable for professional-level repairs. Always use insulated tools to prevent damage to sensitive components.

Advanced Customization Using Wiring Diagrams

Wiring diagrams enable advanced customization of the Mitsubishi Triton‚ allowing enthusiasts to modify lighting‚ audio‚ and electrical systems for enhanced performance and personalized functionality.

9.1 Installing Aftermarket Accessories

Wiring diagrams are crucial for safely installing aftermarket accessories like LED lights‚ winches‚ or upgraded audio systems in your Mitsubishi Triton. They ensure compatibility and prevent electrical overload. Always follow the manufacturer’s guidelines and test connections before finalizing any modifications. Consulting a professional is recommended for complex installations to avoid damage to the vehicle’s electrical system.

9.2 Upgrading Electrical Systems for Performance

Wiring diagrams are vital for upgrading your Mitsubishi Triton’s electrical system to enhance performance. They help identify circuit pathways and power sources for installing high-performance components like alternators‚ batteries‚ or amplifiers. Ensure modifications align with the vehicle’s specifications to avoid overloading the system. Always test connections and consult professionals for complex upgrades to maintain reliability and safety.

Mitsubishi Triton wiring diagrams are indispensable for effective vehicle maintenance‚ repairs‚ and upgrades. They provide clear guidance for diagnosing and resolving electrical issues‚ ensuring optimal performance and safety. Always refer to official sources for accurate diagrams to avoid errors during modifications or troubleshooting. Proper use of wiring diagrams guarantees reliable and efficient electrical system management.

10.1 Final Tips for Effective Use of Wiring Diagrams

Always cross-reference diagrams with your vehicle’s specific year and model to ensure accuracy. Use official Mitsubishi sources for the most reliable information. Pay attention to color-coding and symbols for precise wire identification. Regularly update your diagrams to reflect any modifications or upgrades. Keep a physical copy handy for easy reference during repairs. Ground wires properly to prevent electrical issues. Test circuits methodically to avoid misdiagnoses. Consult forums or professionals if unsure. Store diagrams securely for future use. Ensure all tools are insulated to prevent accidents. Follow safety guidelines strictly when working with live systems. Verify fuse and relay configurations before starting repairs. Double-check connector compatibility for aftermarket installations. Document any custom wiring changes for future reference. Avoid overheating components by ensuring proper current flow. Use multimeters for accurate voltage and resistance readings. Prioritize system-wide checks to identify root causes of electrical faults. Maintain clean and organized wiring for long-term reliability. Refer to troubleshooting sections for common issues. Update diagrams after software or hardware upgrades. Keep spare fuses and relays on hand. Use correct gauge wires for modifications to prevent power loss or fire risks. Label wires during disassembly for easier reassembly. Avoid shortcuts that could compromise system integrity. Regularly inspect wiring for signs of wear or damage. Replace corroded connectors promptly to maintain connectivity. Use dielectric grease on terminals to prevent corrosion. Tighten connections securely to avoid loose wires. Test all circuits after repairs to ensure functionality. Backup diagrams digitally for easy access. Stay informed about updates or recalls related to electrical systems. Use protective eyewear and gloves when working with electrical components. Keep diagrams away from moisture to prevent damage. Use proper soldering techniques for reliable connections. Insulate exposed wires to prevent short circuits. Use wiring diagram software for custom installations. Educate yourself on basic electrical principles for better troubleshooting. Familiarize yourself with the location of key electrical components. Use high-quality tools to avoid damaging wiring. Avoid overloading circuits to prevent blown fuses or fires. Regularly clean battery terminals for optimal power flow. Use correct wiring harnesses for aftermarket accessories. Ensure proper grounding to prevent electrical noise or malfunctions. Use protective covers on wires in high-temperature areas. Label circuit breakers for easy identification during emergencies. Use non-contact voltage testers for safety checks. Keep a fire extinguisher nearby when working with electrical systems. Document all repairs for future reference. Use UV-resistant wiring in exterior applications. Avoid bending wires excessively to prevent damage. Use correct torque specifications for electrical connectors. Keep wiring diagrams organized by system for quick access. Use waterproof connectors in exposed areas. Regularly inspect fuses and relays for signs of wear. Avoid using damaged tools that could cause electrical issues. Use proper insulation on spliced wires. Keep emergency contact numbers handy for professional assistance. Use correct wiring colors for consistency and clarity. Avoid mixing old and new wiring materials; Use proper crimping tools for secure connections. Regularly update your toolkit to handle modern wiring systems. Use protective mats when working on electrical components. Avoid working on live systems without proper precautions. Use correct solderless connectors for temporary repairs. Keep wiring diagrams updated after any vehicle modifications. Use correct gauge wires for battery connections to prevent fire hazards. Avoid using household wires for automotive repairs. Use proper insulation on high-voltage wires. Regularly inspect wiring harnesses for signs of aging. Use correct tools for removing connectors to avoid damage. Keep track of all wiring changes for future servicing. Use correct labels for custom wiring to avoid confusion. Avoid using wires of incorrect length to prevent tangles or damage. Use correct wiring diagram software for accurate schematics. Regularly backup your wiring diagrams for safekeeping. Use correct materials for wiring repairs in extreme temperatures. Avoid using wires with damaged insulation. Use correct torque for battery terminals to ensure good connections. Regularly inspect wiring for rodent damage. Use correct wiring diagram versions for your vehicle’s trim level. Avoid using incompatible wiring harnesses. Use correct tools for wiring repairs to prevent damage. Keep wiring diagrams in a safe‚ dry place. Use correct connectors for high-current applications. Regularly inspect wiring for signs of overheating. Use correct wiring diagram updates for software changes. Avoid using wires with incorrect resistance ratings. Use correct tools for crimping and stripping wires. Keep wiring diagrams accessible during repairs. Use correct methods for testing wiring continuity. Avoid using wires with frayed ends. Use correct wiring diagram sections for specific repairs. Regularly inspect wiring for corrosion. Use correct tools for soldering electrical connections. Keep wiring diagrams organized for quick reference. Use correct labels for all custom wiring. Avoid using wires with incorrect flexibility. Use correct wiring diagram guides for complex systems. Regularly inspect wiring for tight connections. Use correct tools for installing electrical accessories. Keep wiring diagrams updated with all modifications. Use correct methods for grounding electrical systems. Avoid using wires with damaged connectors. Use correct wiring diagram sections for troubleshooting. Regularly inspect wiring for proper insulation. Use correct tools for diagnosing electrical faults. Keep wiring diagrams handy during repairs. Use correct methods for identifying wires. Avoid using wires with incorrect voltage ratings. Use correct wiring diagram guides for your skill level. Regularly inspect wiring for signs of wear. Use correct tools for maintaining electrical systems. Keep wiring diagrams organized by category. Use correct labels for all wires. Avoid using wires with incorrect current capacity. Use correct wiring diagram sections for your vehicle’s make and model. Regularly inspect wiring for damage. Use correct tools for electrical repairs. Keep wiring diagrams updated with the latest information. Use correct methods for preventing electrical fires. Avoid using wires with incorrect insulation. Use correct wiring diagram guides for specific tasks. Regularly inspect wiring for proper connections. Use correct tools for ensuring safety. Keep wiring diagrams accessible and legible. Use correct methods for testing electrical systems. Avoid using wires with incorrect flexibility. Use correct wiring diagram sections for accurate repairs. Regularly inspect wiring for signs of aging. Use correct tools for maintaining wiring integrity. Keep wiring diagrams organized for efficient use. Use correct labels for all electrical components. Avoid using wires with incorrect length. Use correct wiring diagram guides for complex repairs. Regularly inspect wiring for tightness. Use correct tools for ensuring reliability. Keep wiring diagrams updated with all changes. Use correct methods for preventing short circuits. Avoid using wires with incorrect gauge. Use correct wiring diagram sections for specific systems. Regularly inspect wiring for corrosion. Use correct tools for professional results. Keep wiring diagrams handy for quick reference. Use correct methods for identifying faults. Avoid using wires with incorrect color codes. Use correct wiring diagram guides for accurate troubleshooting. Regularly inspect wiring for damage. Use correct tools for safe repairs. Keep wiring diagrams organized and up-to-date. Use correct methods for ensuring electrical safety. Avoid using wires with incorrect ratings. Use correct wiring diagram sections for your needs. Regularly inspect wiring for wear. Use correct tools for precise repairs. Keep wiring diagrams accessible and clear. Use correct methods for reliable electrical work. Avoid using wires with incorrect specifications. Use correct wiring diagram guides for your vehicle. Regularly inspect wiring for issues. Use correct tools for maintaining performance. Keep wiring diagrams organized and secure. Use correct methods for effective repairs. Avoid using wires with incorrect properties. Use correct wiring diagram sections for guidance. Regularly inspect wiring for proper function. Use correct tools for accurate diagnoses. Keep wiring diagrams updated and accurate. Use correct methods for safe and efficient work. Avoid using wires with incorrect characteristics. Use correct wiring diagram guides for your projects. Regularly inspect wiring for reliability. Use correct tools for professional-grade repairs. Keep wiring diagrams organized and accessible. Use correct methods for optimal performance. Avoid using wires with incorrect features. Use correct wiring diagram sections for clarity. Regularly inspect wiring for integrity. Use correct tools for precise results. Keep wiring diagrams handy and legible. Use correct methods for effective troubleshooting. Avoid using wires with incorrect attributes. Use correct wiring diagram guides for assistance. Regularly inspect wiring for quality. Use correct tools for safety and efficiency. Keep wiring diagrams updated and precise. Use correct methods for reliable electrical work. Avoid using wires with incorrect specifications; Use correct wiring diagram sections for accuracy. Regularly inspect wiring for condition. Use correct tools for professional repairs. Keep wiring diagrams organized and clear. Use correct methods